Jennifer Ewoldt, Rural Route 4 columnist

This past week I got to do something that I haven’t been able to do for a while. I helped load a couple of semis of finished hogs headed to market. We have started shipping out our hogs again, as they have reached market weight. Normally, the loads go out on days or times that I cannot help because of my full-time job at the veterinary hospital. However, last week we had two loads the night before my day off, and they were short a helper. When I asked Robb if he needed me to go, I got the famous “Well, we wouldn’t turn it down if you wanted to help, but you don’t have to…..” Which of course means “yes, please.”

So, we all went to bed early and got a couple hours of sleep before getting up at midnight to head to the buildings. The boys came along too, as it was going to be one of their virtual school days that day and they could sleep in a little when we got home. So, it was 1 a.m. and -1 degree F when we got to the buildings. Why do we load at 1 a.m. you ask? Well, it comes down to slaughter plant capacity and distance from the plant.

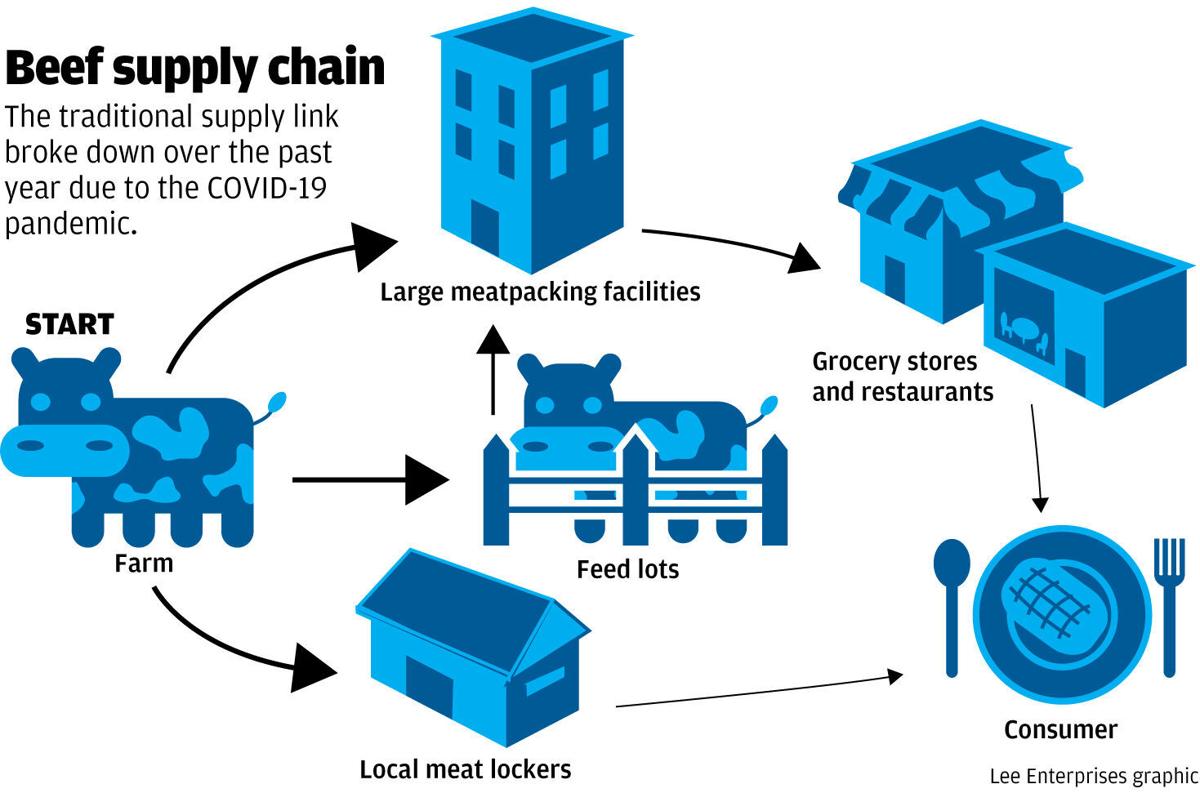

We contract feed for a large pig breeding operation. They supply the pigs and we take care of them and raise them to harvest weight. That company arranges for the space at the processing plant, which is limited based on how many pigs the plant can process at a time. They book the space at the plant, and they get told what time to deliver the pigs. Then they factor in how long it takes the driver to get from our farm to the plant, and that determines when we have to load the pigs.

Sometimes we load late in the evenings, sometimes in the middle of the night, and sometimes early in the mornings. This way, the pigs have the least amount of time to wait on the truck at the plant. Rarely do we load during the day, as the pigs wouldn’t arrive at the plant until afternoon or evening. Wait times can be critical especially in very hot or cold weather, because you don’t want the pigs sitting on a trailer in extreme heat or cold conditions.

As for the cold, you may notice that livestock pots have holes in the sides. These are for ventilation while travelling down the road or sitting still. During the summer, you want all these holes open to allow for maximum ventilation for the animals. There are also roof vents to let in even more air flow. In the winter, however, this is a problem. The trailers are closed up in cold weather with large slats or boards that run from top to bottom of the trailer, covering over the holes. You can put in as many or as few as you need, depending on the outdoor temperature or the animals you are hauling.

Obviously, if you are hauling little baby pigs, you would close it all up to keep them warm. If it’s very cold outside, you would close up most of the trailer even for large pigs headed for slaughter. However, you do need to leave some of the holes open for air flow, as a trailer load of 300 pound hogs generates a lot of body heat. You can see the trailers steaming if they stop in cold weather – that’s all body heat escaping.

We got our pigs sorted out of the pens and loaded that morning. They will be processed into bacon, pork chops, and many foods that you may enjoy eating. We are proud to be Iowa pork producers, producing quality pork products for your table. Enjoy the bacon!

February 01, 2021 at 03:55AM

https://ift.tt/3ctJRQo

Rural Route 4: We are proud to be Iowa pork producers - Quad City Times

https://ift.tt/2RsHZwT

Pork