Nissley Brothers Farm may look like a dairy operation from afar, with several silos and a long barn resembling a freestall structure. But there isn’t any milk shipping out of that busy farm in Mount Joy, Pennsylvania.

There never was.

But there is plenty of beef going to packers and the nearby Vintage Sales Stables. The long barn that gives the farm that dairy appearance actually serves as a feedlot for nearly 500 cattle, and it represents Bernard and Darwin Nissley’s unique approach to raising beef.

The brothers, who are the seventh generation on the farm, took over the operation in 1983, entering the beef business after dabbling in produce and tobacco with their father.

When it came time to transition, the brothers considered a poultry or hog operation, but their preference always came back to cattle.

“My dad always fed cattle in addition to growing tobacco over the summer. When we quit raising tobacco, and the produce industry changed, we decided to go in a different direction,” Darwin said. “We knew cattle.”

Slatted-Floor Barn Makes a Difference

The first large undertaking was a redesign of the 110-foot bank barn built in 1909. The entire bottom portion of the barn was opened up into a spacious bedpack for cows, complete with a manure storage area outside.

Soon after, the brothers removed a tobacco shed and made room for their biggest expansion to date — construction of a slatted-floor barn with manure storage underneath, and enough space to house 500 cattle.

Numerous fans provide plenty of ventilation, and the barn is bright with natural light from two open sides and a curtain system on the west wall.

The barn was completed in 1997, and the Nissleys say the investment has improved the efficiency of their beef operation.

“The slatted-floor building was more expensive than constructing a pen-pack barn, but this works for our operation,” Darwin said. “We have enough manure storage underneath for six months, and we can custom haul the manure in one day. With a pen-pack barn, it would take significantly more time.”

A slatted-floor barn is more common in the dairy industry, and Darwin said most beef producers in his area feed cows out of a bank barn without any manure storage.

The Nissley farm has expanded several times over the years to accommodate the feedlot operation. In addition to a new building, the older bank barn was refurbished to house additional beef cattle.

“They have a skidloader and a spreader. I guess we’re a little bit unique because we have pen-pack storage and a pit for the slatted-floor barn,” he said.

There is enough capacity on the 177-acre farm to hold 800 cows between the slatted-floor building and the bank barn. The Nissleys purchase their cattle as 850- to 900-pound yearlings from backgrounders. Angus is their preferred breed because that’s what the packers desire, Darwin said.

The cows are fed a high-energy ration that includes high-moisture corn, barley when it’s available, and byproducts such as potato chips, candy meal, Pop-Tart filling, cereal and pasta.

Changing Markets

The brothers chose to raise cattle in a feedlot setting because they don’t have the land base to put hundreds of cows out on grass. They rent land to make sure they have enough feed.

“We felt it was better to grow crops, and it’s all marketed through the cattle,” Darwin said.

It proved to be a good choice for the brothers, but they aren’t exempt from the risks that come with selling finished cattle on the market.

Darwin said the feedlot industry has faced a rough time over the last three years, beginning with a fire at a Tyson packing plant in Kansas that shook up the beef market. Last year, COVID-19 forced the shutdown of meatpackers and restaurants, reducing consumer demand for beef.

This year, margins are shrinking in the industry due to high feed costs, and many producers, like the Nissley brothers, are running out of patience.

“It’s very frustrating that our markets aren’t higher than what the retail beef price is,” Darwin said. “Now the demand for beef has returned, but the packers can’t get the labor to process the cattle.

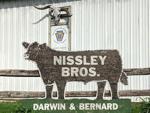

Bernard and Darwin Nissley entered the beef business in 1983 after raising tobacco and produce. They are the seventh generation on the farm in Mount Joy, Pa.

“We’ve been going through this for three years now, and it’s time for the feedlots to get a decent return for their investment.”

Since both brothers are in their early 60s, Darwin said their days of expanding the operation are likely over. But it doesn’t mean they’re ready to exit the cattle business, or lessen their involvement in agriculture, any time soon.

Darwin is a former chairman of the Pennsylvania Beef Council board, and he currently serves with Penn State Extension’s Beef Producers Working Group, the Pennsylvania Cattlemen’s Association board and the Agricultural Advisory Board for the state Department of Environmental Protection.

“I don’t ever regret expanding into the cattle business,” Darwin said. “There are ups and downs and not every year is going to be a good one, but I like the independence and I enjoy working with cattle. If you’re doing something you enjoy, it’s not hard to put that 110% into it.”

The Link LonkMay 21, 2021 at 05:15PM

https://ift.tt/3hIavYn

Feedlot Works Best for Beef Brothers | Beef & Cattle Farming News | lancasterfarming.com - Lancaster Farming

https://ift.tt/2RxTDX4

Beef

No comments:

Post a Comment